Moisture Management for Textile

Importance of Moisture Management:

Human body acts like an air conditioning. This sophisticated system reliably regulates our body temperature. An essential control mechanism of this system is the release of moisture at the right moment to protect the body from overheating.

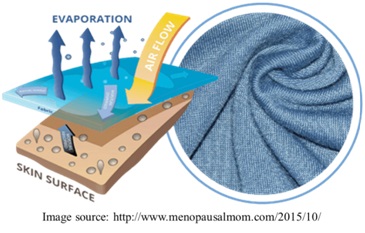

Moisture Management is the ability of a fabric/garment to manage the moisture (primarily sweat) by transporting (or ‘wicking’) moisture away from the skin to the garment’s outer surface, thus preventing perspiration from remaining next to the skin.

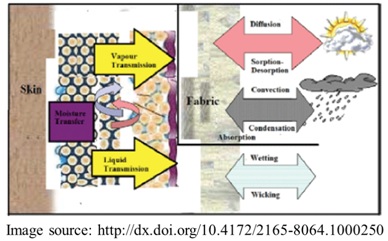

Schematic representation of pathways for moisture loss from the body

In hot conditions, trapped moisture may heat up and lead to fatigue or diminished performance. In cold conditions, trapped moisture will lead to drop in temperature and cause chilling and hypothermia. Excess moisture may also cause the garment to become heavy, as well as cause damage to the skin from chafing.

Factors responsible for Moisture Management by textile:

The main aim of moisture management fabric is to make the skin feel dry. In order to achieve this, humidity should be evaporated and transferred to the atmosphere as soon as possible. This is achieved by a number of factors. Two most prominent ways are as follows:

- Capillary action – Moisture is transported in textiles through capillary action or wicking. In textiles, the spaces between the fibres effectively form tubes, which act as capillaries, and transport the liquid away from the surface. As the gaps between the individual fibres becomes thin the force increases. Thus, finer fibres will have smaller gaps and better humidity transport. The evaporation of the humidity depends on the surface area of the textile used. As the surface increases, fibres are finer and hence more fibres at the surface and faster humidity evaporation.

- Absorbency – greater absorbency increases the ability for moisture to be drawn into the fabric. However, the tendency of absorbent fibres to retain such moisture affects comfort levels, as the garment becomes saturated.

Transport Mechanism:

Water vapour and liquid water make their way across a fabric by following mechanism:

1) Simple diffusion through inter yarn spaces: Diffusion is the main mechanism for transferring moisture in low moisture content conditions. This process is controlled by the water vapour pressure gradient across the inner and outer faces of the fabric. The resistance to diffusion is governed by the fabric construction, i.e., the size and concentration of inter yarn pores and the fabric thickness.

2) Capillary transfer through fibre bundles: this way the liquid water is ‘wicked’ through the yarns and desorbed or evaporated at the outer surface. The efficiency of yarn working depends on the surface tension, i.e., wettability of the fiber surfaces, and the size, volume and number of capillary spaces is determined by the choice of yarn and fabric construction.

3) Diffusion through individual fibres: This mechanism involves absorption of water vapour into the fibres at the inner surface of the fabric, diffusion through the fibre structure, and desorption at the outer surface. The ability of fibres to undergo water vapour diffusion depends on the hydrophilic or hydrophobic nature of the fibre.

Moisture Management Approaches:

Several approaches have been tried out to achieve moisture management property in textiles. The approaches take into consideration one or more routes of water (moisture or liquid) evasion from skin towards outside.

While different manufacturers target different steps of moisture transport mechanisms, the basic idea aims at keeping the skin side of the fabric dry and facilitate quick evaporation from the face side of the fabric.

Some of the examples (but not limited to these) are as below:

- “Push-pull” fabrics – bi-component materials, composed of a non-absorbent material on the inside and an absorbent material on the outside, have proved to be an effective construction for moisture management fabrics. This is because the absorbent material on the outside draws the moisture away from the skin while the non-absorbent material keeps the skin dry. The face being exposed on the outside, dries quickly in spite of being hydrophilic.

- Quick spreading fabric: these type of fabrics rely on the fact that by quickly spreading the moisture quickly across the fabric surface, drying is accelerated. Quick spreading of moisture on the face side also leads to a source-sink condition across the fabric and the sweat is drawn faster towards the face side.

- Increase in spread area: Apart from the spreading speed, it is also important that the face side of the fabric is able to spread water over a large area, so as to increase the surface area for rapid evaporation.

While push-pull function can be achieved by varying composition and/or yarn type, quick and wider spreading is usually achieved by creating micro-channels on the face of the fabric, either by using fine fibers/yarns or by varying the shape (or cross-section) of the yarn.

Requirements of a moisture management fabric:

Apart from basic moisture management attributes, idea properties of a moisture management fabric have the following attributes:

- Optimum heat and moisture regulation

- Rapid moisture absorption and transfer capacity

- Absence of dampness

- Rapid drying

- Low water absorption on skin side of the fabric

- Dimensionally stable even when wet

- Durable and easy care

- Breathable and comfortable

- Soft and pleasant touch

- Smart and functional design

Important Test Methods:

- Absorption of textile, Drop Wick Test (AATCC 79)

The absorbency of yarns or textile fabrics can be determined by this test method. Often interchanged with the term wettability, the absorbency characteristics of a fabric can influence the uniformity and completeness of bleaching and dyeing by the ability to take in water into the fiber, yarn, or fabric construction.

A drop of water is allowed to fall from a fixed height onto the taut surface of a test specimen. The time required for the specular reflection of the water drop to disappear is measured and recorded as wetting time.

- Liquid Moisture Management Properties of Textile Fabrics (AATCC 195)

The liquid moisture management properties of a textile are evaluated by placing a fabric specimen between two horizontal (upper and lower) electrical sensors each with seven concentric of pins. A predetermined amount of test solution that aids the measurement of electrical conductivity changes is dropped onto the center of the upward-facing test specimen surface. The test solution is free to move in three directions: radial spreading on the top surface, movement through the specimen from top surface to the bottom surface, and radial spreading on the bottom surface of the specimen. During the test, changes in electrical resistance of specimen are measured and recorded. The electrical resistance readings are used to calculate fabric liquid moisture content changes that quantify dynamic liquid moisture transport behaviours in multiple directions of the specimen. The summary of the measured results are used to grade the liquid moisture management properties of a fabric by using predetermined indices.

This test monitors the absorption and spreading of simulated sweat on both the top and bottom of a fabric sample. Additionally, it also measures parameters such as one-way transport capacity and OMMC (Over-all Moisture Management Capacity) of the fabric in question. Based on the readings against the parameters, the test helps to define the test fabric into a particular category, e.g. ‘fast spreading quick drying’, ‘quick absorbing fabric’, ‘moisture management fabric’, etc.

- Vertical Wicking of Textiles (AATCC 197)

This test method is used to measure “the ability of vertically aligned fabric specimens to transport liquid along and/or through them. Wicking rate is a particularly important property that measures a fabric’s ability to remove sweat from contact with the body. Gravity plays a role in this test method.

- Horizontal Wicking of Textiles (AATCC 198)

The test method is similar to AATCC 197, except that horizontally aligned fabrics are tested. Wicking rate is also evaluated here, although without the influence of gravity.

- Drying Time of Textiles: Moisture Analyzer Method (AATCC 199)

This test method can be used to determine the drying time for fabrics at an elevated temperature (including skin surface temperature of 37°C) using a gravimetric moisture analyzer. Drying time at body temperature is critical. Once moisture has been transported to the outside of the fabric, it should be evaporated away quickly, and this test method evaluates the fabrics ability for this particular phenomenon.

- Drying Rate of Textiles at their Absorbent Capacity: Air Flow Method (AATCC 200)

The test method follows a procedure that allows drying rate determinations at the test specimen’s absorbent capacity (i.e., “the maximum amount of liquid a material can hold; dependent on the specific test method used.”)

- Drying Rate of Fabrics: Heated Plate Method (AATCC 201)

This tests, as the name suggests, measures the rate at which a prescribed amount of water evaporates from a fabric subjected to 37°C or elevated/exercising skin temperature and a constant airflow.

- Water Vapour Transmission of Textiles (AATCC 204)

Developed specifically to evaluate comfort of vapour permeable textiles used in outdoor products, this test method is used to determine the relative rate of water vapour transmission of textiles. The temperature differential between the heated bath and the ambient air creates a driving force to promote water vapour transmission.

- WATson (Hohenstein Institute)

The test, developed at Hohenstein Institute (Germany), is a versatile thermal testing for special conditions. The testing device, designed for this test has a heated measuring head with fast response time to simulate the warmth sensation of human skin. Various ambient climates (hot/humid – cold/dry) and numerous edge conditions (sweat, wind, and sun) are simulated in order to get as real-time conditions as possible.

The test measures average cooling power and cooling power over time and duration and intensity of the cooling, making it a more complete information.

Conclusion:

Irrespective of the season, moisture management is always an essential component in fabric’s performance in a garment, especially when it is next to skin. While an effective moisture managing fabric can make the wearer’s life easy, a poorly fabric, in terms of moisture management, is a trouble.

The mechanism of water (liquid or vapour) transport across a fabric is well understood and manufacturers are focusing of some or all aspects of the process. Focus is also on achieve superior moisture management by yarn technologies, rather than finishes, for the obvious advantage of durability. Scores of test methods have been established to quantify the performance of moisture management fabrics, depending on what aspect of the mechanism the fabric is expected to perform.

Share This Post