Antimicrobial Technology for Textile Industry

1. Introduction

Owing to the large surface area and ability to retain moisture, textile structures are prone to microorganisms’ growth, which causes a range of undesirable effects, on the textile itself as well on the user. With the growing public health awareness of the pathogenic effects, malodours and stain formations caused by microorganisms, there is an increasing need for antibacterial materials.

The strategy to impart an antimicrobial ability to textiles has been divided into two approaches:

- Inclusion of antimicrobial agents in the fibers (Yarn inherent)

- Grafting onto the polymer surface (topical treatment)

2. Antimicrobial modes of action

In general, the antibacterial agents, used in textile industry, act to control the microbial effects by one the following modes:

- Damage or inhibition of cell wall synthesis

- Inhibition of cell wall function

- Inhibition of Protein Synthesis

- Inhibition of Nucleic acid Synthesis

- Inhibition of other metabolic processes (e.g. folic acid pathways)

3. Expectations from Antimicrobial treatments

Apart from effectively acting against microbial population and preventing the fabric (and the wearer) from its effects, antimicrobial treatment are required to fulfil the following requirements as well:

- Suitable for textile processing

- Durability to laundering, dry cleaning and hot pressing

- Favourable safety and environmental profile

- No change in textile quality and appearance

4. Most common antimicrobial agents for textile industry

4.1 Quaternary Ammonium Compounds (QACs)

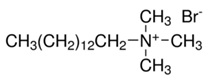

QACs are molecules with a positive charge at the N atom in the solution, usually attached to an anionic fiber surface (R4N+X–), e.g. Trimethyltetradecyl ammonium bromide

The structure primarily consists of a hydrophobic alkyl chain and a hydrophilic counterpart. In textile industry, usually 12-18 carbon atom alkyl chain is used.

4.1.1 Mode of Action

QACs act by interaction of surface positive charge and cell membrane negative charge followed by:

- Damage to cell membrane and cell leakage,

- Denaturation of proteins, and/or

- Inhibition of DNA production

The extent of their action depends on three important factors:

- Alkyl chain length

- Presence of perfluorinated group

- Cationic ammonium group’s number in the molecule

4.1.2 Advantages of QACs

- High level of effectiveness

- Ease of application

4.1.3 Disadvantage of QACs

- Leaching due to absence of physical bonding with the textile surface

4.1.4 Commercially Available QACs:

- BioGuard® (AEGIS Microbe Shield™)

- Sanigard KC (L.N. Chemical Industries)

- Sanitized® (SANITIZED)

4.2 Triclosan

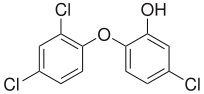

Triclosan is an odorless synthetic chlorinated bisphenol. It is an antibacterial and antifungal agent commonly used in consumer products, including toothpaste, soaps, detergents, toys, and surgical cleaning treatments.

(2,4,4’-trichloro-2’hydroxydiphenyl ether or C12H7Cl3O2)

4.2.1 Mode of Action

Triclosan work by blocking lipid biosynthesis leading to severely affecting cell membrane integrity.

4.2.2 Pros

- Does not ionize in solution, improving its durability to laundering

- Active against Gram-positive and Gram-negative bacteria and some fungi and viruses

4.2.3 Cons

- Potential for selective pressure for some anti-biotic cross-resistant strains, generating bacterial resistance to triclosan

- Possible photochemical conversion of triclosan to 2,8-dichlorodibenzo-p-dioxin (in aqueous solutions), which is toxic

4.2.4 Commercially available products based on Triclosan

4.2.4.1 Finishes:

- Irgagaurd® 1000 (BASF (Ciba))

- Irgasan (Sigma Aldrich)

- Microban® (Microban International)

4.2.4.2 Yarn Inherent:

- Amicor/Amicor Plus (Acordis Ltd.): Acrylic with triclosan (or triclosan + tolnaftate)

- BiofresH™ (Sterling Fibers, Inc.): Acrylic fiber with triclosan

- Silfresh® (Novaceta): Cellulose acetate with triclosan

4.3 Metal Metallic salts

Non-essential metals, toxic to most microbes even at very low concentrations. They are primarily used in three forms (free-state, oxides and salt compounds) mostly based on Silver (Ag), Zinc (Zn), Cobalt (Co), etc. Salt based additives are the most common form as the metal forms are highly expensive.

4.3.1 Mode of Action

The mode of action of metal salt depends on the metal. It can be triggered by metal reduction potential and/or metal donor selectivity and/or speciation (formation of new species). These redox-active essential metals generate or catalyse reactive oxygen species which can induce oxidative stress, damaging cellular proteins, lipids and DNA. In general, external metal ions or complexes can replace original metals present in biomolecules (e.g. Fe-S cluster) leading to cellular dysfunction.

Metallic silver (which gives ions when reacts with moisture) and silver ions damage bacterial DNA and RNA, inhibiting their replication.

Nanoparticles present high surface area and can dissolve faster, releasing higher amount of metal ions and delivering a stronger antimicrobial activity. E.g. Silver, CuO, ZnO, TiO2. Antimicrobial activity is inversely proportional to nanoparticle size. ZnO has been reported to present better antimicrobial activity than other metal oxides (e.g. SiO2, MgO, TiO2, etc)

Composites: ZnO nanoparticle-Chitosan composite: much higher antimicrobial activity than both, better chemical bonding assisted by chitosan

4.3.2 Advantages

- Wide range of anti-microbial activity (Gram +ve and Gram –ve)

- Ease of use

4.3.3 Disadvantages

- Bacterial resistance to silver based products

- Leaching out for topical finishes

4.3.4 Commercially available products

4.3.4.1 Finishes

- Agion® (Sciessent): Silver + zeolite

- AlphaSan® (Milliken Chemical): Silver

- Silpure® (Thomson Research Associates): Silver

- SilvadurTM (The Dow Chemical Company): Interpenetrating polymer network with silver ions

- SmartSilver® (Nanohorizon Inc.): silver nanoparticles

- Silvérion 2400 (Pure Bioscience, Inc.): Stabilized silver complex

- Saniguard Nano-ZN (L.N. Chemical Industries): aqueous nano-dispersion of ZnO

4.3.4.2 Yarn inherent

- Bactekiller® (Fuji Chemical Industries, Ltd.): metal ions

- Bioactive® (Trevira): Polyester fibers containing silver

- FeelFresh® (Toyobo): Acrylic fiber with metal ions

- MicroFresh® and Solefresh® (O’Mara, Inc.): polyester with silver particles

- SeaCell® Active (Smartfiber AG: SeaCell fibers (cellulose based) with silver particles

- Thunderon (Nihon Sanmo Dyeing Company, Ltd.): Acrylic fibers with copper ions

4.3.4.3 Textile Structure

- Acticoat® (Smith & Nephew): 3 layers (2 layers of polyethylene mesh coated with nanocrystalline silver, one layer of rayon or polyester)

4.4 Chitosan

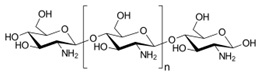

Chitosan is a natural and hydrophilic copolymer made by deacetylation of Chitin. The structure consists of two monomers (D-glucosamine and N-acetyl-D-glucosamine) linked by β(1-4)-glycosidic bond

4.4.1 Mode of Action

Step 1:

Interaction between primary amine’s +ve charge and -ve charge on cell membrane

Step 2:

Low Mw: Cell wall penetration, interaction with DNA and inhibition of mRNA synthesis

High Mw: Change is cell membrane

(1) Increased cell permeability and leakage of intracellular substances

(2) Formation of impermeable layer around cell, blockage of transport of essential solutes into the cell

4.4.2 Advantages of Chitosan

- Excellent antimicrobial activity

- Biocompatibility

- Non-toxicity

- Non-carcinogenicity

4.4.3 Disadvantages of Chitosan

- Poor handling

- Soluble only in acidic condition

- Strong activity in acidic environment

- Biocidal effectiveness changes significantly during storage and with temperature

4.4.4 Commercially available products based on Chitosan

4.4.4.1 Finish

- Eosy® (Unitika)

4.4.4.2 Yarn Inherent/composite:

- Chitopoly® (Fuji-Spinning): fiber made by kneading chitosan into polynosic fiber

- Crabyon® (Swicofil AG): composite fiber (Chitin/Chitosan + cellulose viscose)

4.5 Natural-based Antimicrobial Agents

Many antimicrobial compounds extracted from herbs and plants have been studied as an alternative strategy to combat microbial growth on textiles.

The most common category among these agents is that of antimicrobial peptides. Antimicrobial Peptides (AMPs), also called host defence peptides (HDPs), are part of the innate immune response found among all classes of life. These are small size (15-20 amino acids) natural defensive peptides. Antimicrobial peptides have been demonstrated to kill Gram negative and Gram positive bacteria, enveloped viruses, fungi and even transformed or cancerous cells.

Apart from AMPs, various other plant based antimicrobial agents, e.g. Terpenoids, Flavonoids, Quinones, Tannins, Coumarins, etc., have been studied and used commercially.

4.5.1 Mode of Action

Multiple mechanisms, avoiding selection of resistant bacteria strains

– Arginine and lysine residues for positive charge and an amphipathic structure to interact with microbial membrane

– Effects on internal cellular processes e.g. macromolecular (RNA, DNA, etc.) synthesis, loss of ATP, etc

4.5.2 Advantages

- Do not exhibit side effects

- No reports of antimicrobial resistance

4.5.3 Commercially used compounds

Many AMPs are in medical use (e.g. daptomycin, pexiganan, psoriazyna, etc.) but very few have been there for use in textiles and fiber use. L-cystine has successfully been used to promote biofunctionalization of wool and nylon for durable antimicrobial effect.

4.6 Poly(hexamethylene Biguanide) (PHMB)

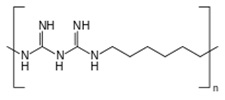

PHMB is a polycationic amine with a hydrophobic backbone in which cationic biguanide groups are interspersed between hexamethylene groups

4.6.1 Mode of Action

– Interacts with cell membrane by electrostatic and hydrophobic interactions

– Cell membrane disruption and lethal leakage of cytoplasmic materials

4.6.2 Commercially available products:

4.6.2.1 Finishes:

– Biozac ZS (Zschimmer & Schwarz Mohsdorf GmBH @ CoKG)

– Cosmocil™ CQ (Lonza)

– Reputex™ (Lonza)

4.6.2.2 Material integrated:

– Kendall™ (Medtronic): Textile foam dressing with PHMBs

4.7 N-Halamines

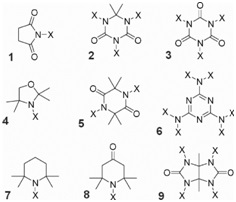

N-Halamines are heterocyclic organic compounds with one or two covalent bonds between nitrogen and halogen (N-X, especially Cl, Br and I). Some examples of N-Halamines are:

– Order of stability imide < amide < amine (So, for sustained antimicrobial properties amine N-halamine is preferred)

4.7.1 Mode of action:

– triggered by electrophilic substitution of Cl with H in presence of water. Free Cl- binds to microbes’ receptor regions, precluding the cell enzymatic and metabolic process leading to their destruction

– Order of effectiveness imide > amide > amine (so for rapid antimicrobial destruction imide N-halamine is preferred)

4.7.2 Advantages

- Stable compounds

- Low cost

- Possibility of constantly recycling by recharging using halogen donor compounds (using a bleaching solution during laundering)

4.7.3 Disadvantages

- Substantial amount of absorbed Cl or other halogens on fiber surface

- Unpleasant odor

- Discoloring of fabric

5. Conclusion

The rapidly growing awareness for active lifestyle and the associated demand for comfort, hygiene and well-being, concerning odor control and microorganisms protection, has created a large and rapidly increasing market for the expansion of antimicrobial textiles. Textile industry have reacted to this demand by coming up with range antimicrobial agents, to be applied at the finishing stage or incorporated into the yarns.

Despite the advantages offered by antimicrobial textiles there have been concerns associated, e.g. bacterial resistance promoted by the agents, their toxic breakdown products and the consequent risks to human health and environment balance. It is imperative that the long-term benefits and potential problems associated with antimicrobial textiles should be simultaneously considered and closely monitored to avoid the problems overpassing the benefits. So, more importance must be given to develop more environment-friendly techniques and to promote the usage of “green” agents, which have revealed potential antimicrobial effects without adverse effects.

Share This Post